Contact: +91 99725 24322 |

Menu

Menu

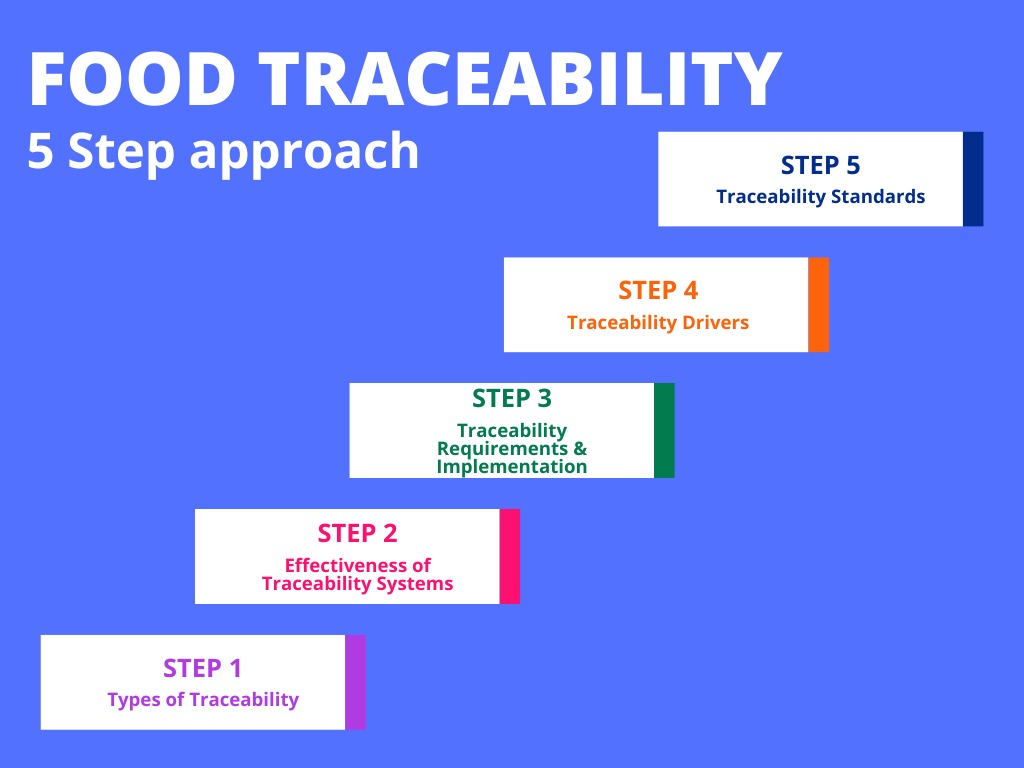

Quick summary: The ability to follow the movement of food products and their ingredients throughout the supply chain both upward and downward is known as traceability. The need for Food traceability arises from two different ends of the spectrum, the producer and the consumer. Let us understand the 5-step approach to food traceability

The various scandals rocking the food industry over years has disrupted the food ecosystem and shattered the confidence of end consumers. Food Recalls and Food Safety has become a major concern in the Food industry. Governments, companies and the end consumers want to know how the foods they purchase were prepared and where it came from. The food industry has to bring in this transparency in order to thrive in this market. Food Traceability is an important component of a business’s overarching Food Safety program.

“The ability to follow the movement of food products and their ingredients throughout the supply chain both upward and downward is known as traceability”. It is a system that links the production, processing, and distribution and makes it possible to locate a product at any given stage in the supply chain.

Today both the consumer and the producer want their product to be of the highest quality.

A consumer has every right to know about the origin of the product, common allergens used in the process, and the organic raw materials sourced.

Meanwhile, the producers want to build trust among the customers by providing quality and valid data certificates about the product.

According to the World Health Organization an estimated 600 million – almost 1 in 10 people in the world – fall ill after eating contaminated food and 420 000 die every year. In the Global market, food safety and management issues have to align with the food safety systems, internal and external to the supply chain.

The proper sourcing of raw materials along with strict processing norms and proper documentation will help in adhering to safety concerns. To achieve such safety, systematic management, track, and trace solutions are vital. Food traceability helps in product recalls and timely withdrawals of products in the food chain.

Contamination in the food supply chain happens in two ways, one being due to external factors like change in weather, temperature, seasonal products, transportation, and mismanagement, and the other one due to internal factors like counterfeiting and misrepresentation, substitution, dilution, adulteration, etc.

1Between January and March 2020, FDA issued 141 food recalls affecting 8.8 million units of food. During the second quarter, there were 79 recalls, affecting more than 7.8 million product units.

The advent of Blockchain technologies has given an impetus to traceability systems.

The use of Blockchain technology helps in tracing, tracking, and recall of such products and counter contamination.

Check how blockchain helps product recalls

With the help of Food traceability, both external and internal factors of contamination can be mitigated to a certain extent. With proper tracking of information throughout the supply chain, tracing products has become much easier.

Check out the 6 best practices in Food Traceability

Tracking and Tracing in the food supply chain is important to ensure food safety and compliance with regulations. This involves:

Tracking and Tracing enhance the efficiency of a food supply chain, guaranteeing a safe and a quality product to the consumer and at the same time adhering to the necessary standards and regulations. Check out the best practices that can be adopted in food traceability

Building sustainable and safe brands to win consumer loyalty and good intent needs credibility of claims to stand apart. Catch customers able to trace the bean to cup journey of SLAY coffee with blockchain traceability solutions

This type of traceability allows you to track a product from its origin at the farm all the way to its final destination, the supermarket shelf. This means that the product can be traced forward in time and space from the point of production to point of consumption and ensure that the product is safe and meets the regulatory requirements throughout its journey in the food supply chain.

This type of traceability allows you to track a product from the retail shelf back to its origin, the farm. This means that the product can be traced backward in time and space from the final destination to the source of origin. This helps to identify the source of problems that could arise due to food contamination and disease outbreaks, thereby aiding in food recalls.

This type of traceability allows you to track a product within a specific facility or location, such as a processing plant or warehouse. This is important for ensuring that products are handled and processed correctly and for identifying any issues.

This type of traceability allows you to track a product as it moves between different facilities or locations in the supply chain. This is important for ensuring that products are properly handled and transported throughout the supply chain and for identifying any issues that may arise during transportation.

Each type of traceability is important to ensure the safety and quality of the product. The end-to-end traceability brings visibility and transparency in the food supply chain, winning consumer’s trust in the food they eat.

The effectiveness of a traceability system is crucial to ensure they are working efficiently and effectively.

Measuring the effectiveness of a traceability system is a must to ensure that the systems are functioning to deliver the benefits cited.

Mapping traceability requirements and implementation is an important step towards ensuring an effective traceability system. Identifying and documenting the various stages in the supply chain and tracking and recording data at each stage is vital. Some of the key steps are:

Mapping traceability requirements helps to have a comprehensive traceability system in place which can enable track and trace of products in the supply chain. This improves food safety and satisfies regulatory requirements

The implementation of Food traceability has to do with three major players in the Food industry.

Producers: With the global market in place, the need of the hour is quality, time, and cost. Manufacturers are adopting internal traceability software to ensure food safety and traceability to achieve consumer trust. The quality management of ISO 22000 requires traceability.

Consumers are demanding greater transparency and accountability from companies around food safety, sustainability and ethical practices. Traceability enables transparency and visibility across the supply chain , thereby building consumer trust.

Traceability helps companies to identify risks associated with issues related to food contamination and disease outbreaks. This helps to mitigate reputational and financial risks associated with product recalls or supply chain disruptions.

Traceability can help companies to demonstrate their commitment to sustainability and providing visibility into the environmental and social impact of their products. This provides a competitive edge to the companies who assure a trustworthy brand.

Traceability helps companies to optimize their supply chain operations by providing real-time capability of data capture all along the supply chain. This improves efficiency, reduces waste and minimizes costs.

Traceability enables companies to be compliant with the regulatory standards by providing a transparent and auditable record of the product’s journey through the supply chain.

These drivers demonstrate the importance of traceability as a must have for companies to meet consumer demands and satisfy the regulatory markets

Private standards for traceability can help companies ensure that their products are responsibly sourced, meet the expectations of consumers and the stakeholders and comply to the relevant regulations and standards.

Private standards for traceability are developed by industry groups or private organizations to meet specific requirement related to traceability of materials or products.

The roots of most of the food safety problems starts at the farm at the production site. There is a need to understand the food production practices and how the food travels through the different stages of processing, transport, storage, distribution and consumption. This helps in reducing business risks and avoids costly food recalls. The farmers today lack the knowledge and resources to manage their farms and realize higher and quality yields. The need to track and monitor the environmental and supply chain variables through technology and at the same time comply to regulations mandates the necessity of farm management solutions

Farm Management software will enable traceability in food supply chains. A SaaS platform that provides complete traceability solutions right from farm management practices like agronomy practices, crop and harvest management, and data management helps to build a robust food supply chain. Data-driven solutions make the agriculture supply chain more sustainable and efficient and easily traceable. Blockchain traceability with tagged QR codes recreates the product story and assures the consumer of a transparent journey of the product.

raceX’s blockchain-powered SaaS platform brings the required transformation in food supply chains to ensure trust and transparency in the food ecosystem. The farm management solutions help the farmers to improve the quality and increase their yields with streamlined pre-harvest and post harvest management. Trace Gro and Trace Pro modules of TraceX builds an end to end traceability system that provides farmers the benefits of taking data driven decisions, guarantees enhanced operational efficiency and safe food for the end consumers.

Check out how Farm Management Solutions from TraceX helps to build end to end traceability in agriculture supply chains

Food Traceability is emerging as an important link in global food trade and making agriculture environmentally friendly.