Contact: +91 99725 24322 |

Menu

Menu

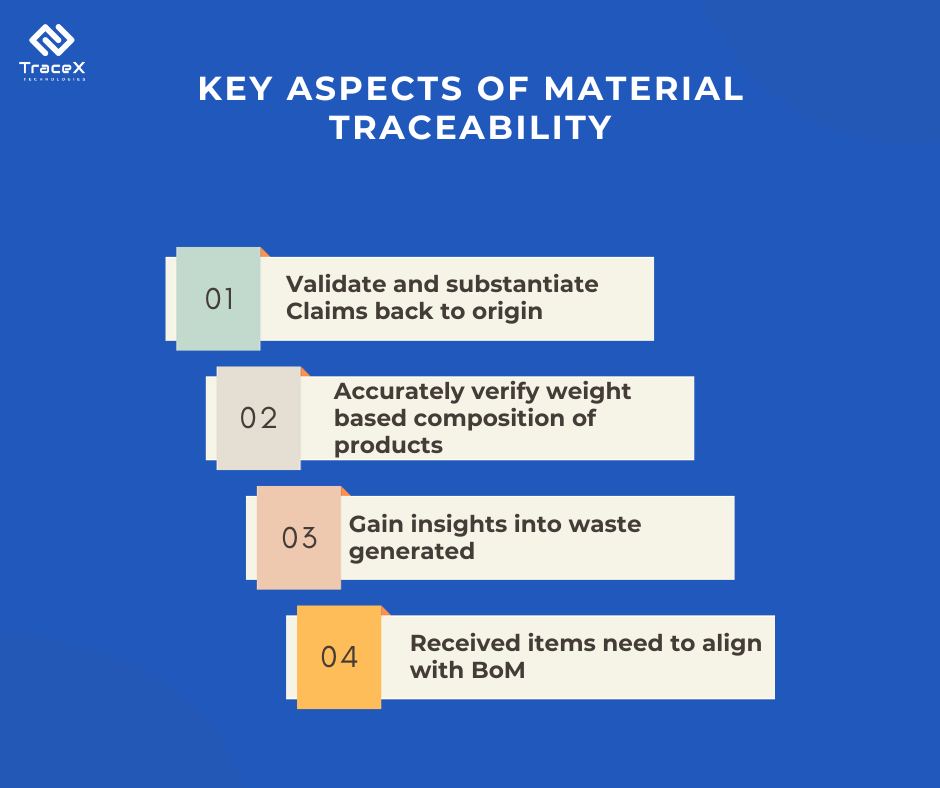

Quick summary: Uncover the essentials of tracking materials across the supply chain, from origin to final product. Gain insights into the significance of material traceability, its impact on quality, compliance, and sustainable practices. Elevate your understanding and optimize your supply chain with this insightful read. Explore now for a deeper insight into material traceability in modern supply chains.

In the labyrinth of global supply chains, understanding the provenance and journey of materials has become an indispensable aspect of responsible and efficient business practices. Material traceability, the systematic tracking and tracing of raw materials through various stages of production, is emerging as a linchpin for industries seeking transparency, compliance, and risk mitigation.

In this blog, we will unravel the layers of material traceability, delving into its definition, multifaceted importance, supply chain implications, key components, technologies, benefits, challenges, and ultimately, its transformative impact on the future of responsible business.

Material traceability is about more than just tracking goods from point A to point B; it’s about understanding the story behind each material. It’s the tale of its origin, the people involved, and the journey it embarks upon. At its core, material traceability is a commitment – a commitment to quality, ethics, and the well-being of both the business and the end consumer.

In recent times, the significance of traceability has escalated for manufacturing enterprises. The proliferation of global supply chains has added complexity to ensuring that products adhere to quality standards and comply with regulations. Material traceability has emerged as a pivotal strategy, enabling companies to detect potential issues early in the production processes and implement corrective measures proactively, averting major problems.

Moreover, traceability plays a vital role in managing product specifications and their dissemination to factories and subcontractors. By meticulously tracking the distribution of specifications for materials and products, companies can verify adherence to standards, ensuring that factories and suppliers are in compliance. Material traceability goes beyond mere serial- and batch control; it stands as a crucial contributor to the development of digital threads and digital twins in the manufacturing landscape.

Identification and Labelling

Data Capture and Recording

Digital records

Supplier Collaboration

Quality Control

Integration with production processes

Real time Monitoring

Regulatory Compliance

Chain of Custody

Recall Management

The significance of material traceability resonates from diverse perspectives, each contributing to the overall success and sustainability of businesses.

Material traceability extends its influence across the entire supply chain, impacting various stakeholders and processes.

The adoption of material traceability yields a multitude of benefits that extend beyond compliance requirements.

While the benefits are evident, implementing and maintaining effective material traceability systems come with their set of challenges.

Technological advancements have significantly enhanced the capabilities of material traceability, introducing innovative solutions to streamline the tracking process.

TraceX blockchain-powered traceability solutions play a pivotal role in enhancing material traceability by leveraging the inherent features of blockchain technology.

Every transaction related to materials, from production to distribution, is securely recorded and visible across the supply chain. Materials are assigned unique cryptographic identifiers stored on the blockchain, ensuring secure and tamper-proof identification. This prevents the risk of counterfeiting or fraudulent activities within the supply chain. Blockchain provides end to end visibility into the journey of materials, allowing stakeholders to trace their origin, processing, and distribution. This transparency fosters trust among supply chain participants and consumers. All participants in the supply chain, including suppliers, manufacturers, distributors, and retailers, share a synchronized view of material data, promoting real-time collaboration. In the event of a product recall, blockchain-powered traceability simplifies the identification and isolation of affected materials. Companies using blockchain-powered traceability solutions find it easier to demonstrate compliance with regulatory requirements.

TraceX solutions are designed for seamless integration with existing systems, ensuring a smooth transition to blockchain-powered traceability without disrupting established workflows.

Conclusion

Material traceability is not merely a logistical necessity but a strategic imperative for businesses navigating the complexities of modern supply chains. From compliance and risk mitigation to ethical sourcing and consumer trust, material traceability weaves a thread that connects stakeholders across the entire supply chain. As technologies continue to evolve, businesses embracing and investing in robust material traceability systems are not only meeting current expectations but are also laying the foundation for a sustainable and responsible future. In the intricate tapestry of global commerce, understanding the path of materials is not just a requirement – it’s the key to unlocking a future where transparency, accountability, and ethical practices reign supreme.