6 Main Objective of the Food Supply Chain in India

Quick summary: The food sector in India is going through a massive transformation. With the increasing demand for quality and safety standards, increasing efficiency, and integrating small farmers into the value chain, an integrated perspective of the supply chain is required. The main objective of supply chain management is to reduce cost, improve organizational performance and provide satisfaction to the consumer.

For every industry to perform well there has to be a definite process or rules that help in its systematic and effective execution. The food industry is no special, food; a necessary commodity is produced daily, consumed daily and wasted daily.

Its marketplace is the entire world; the food industry has encapsulated the world as a single marketplace through globalization. An increase in population has forced the industry to increase production and in turn, there has been an increase in food waste, these food wastes have a close link with Global warming.

As per the United Nations report, 14% of food production is lost between harvest and retail, and 17% of total food production is wasted. These sums up to around 1.3 billion tons of food waste.

The majority of this waste is dumped in landfills which account for the release of greenhouse gasses. Sustainable use of available resources is a major task in the efficiency of a supply chain. Therefore, for the smooth and effective functioning of such a huge industry, food supply chain efficiency and management are vital. Technological implications have helped the industry to progress and keep up with the global requirements. A major part of which is the supply chain management. Check out the 5 factors that influence Supply Chain Management

Supply Chain Management

Good supply chain management involves certain aspects,

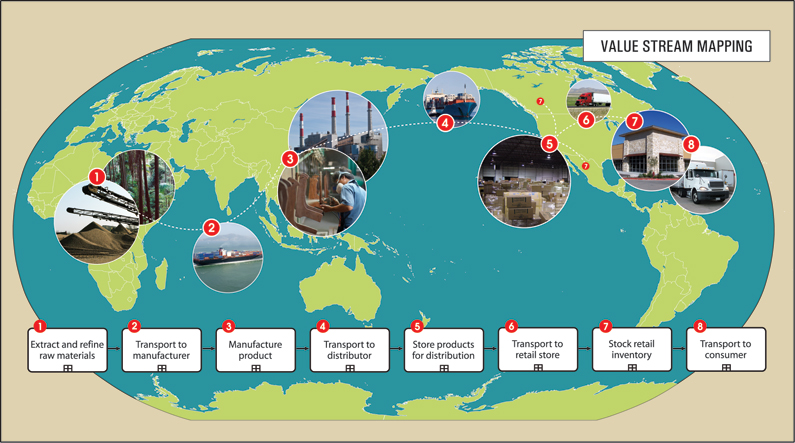

The Supply Chain: The prima facie of the food industry is its supply chain. Therefore, a proper supply chain has to be in place to manage operations, distribution, marketing, financials, and customer service along with maintaining transparency, efficiency, consistency, and timeliness.

Stakeholder Connections: Major part of supply chain management is maintaining a relationship between players in the supply chain. These relationships are critical because the supply chain is a continuous and time-limiting process. All operations are to be performed within a given time and with high efficiency and with collaboration.

Sourcing, operating and delivery: Quality of products can be achieved through quality sourcing. Sourcing is done by taking into account demand, trends and consumer tastes. Processing activity happens in synch with the sourcing, linking and logistics of raw materials through processing is performed. Today’s market USP is faster delivery. Integrated distribution channels help in timely delivery.

Return/ Recall: For quality and safety purposes, supply chain management uses the recall of products feature. Here recall not only refers to the recall of products from the consumers but also the return of defective expired or low-quality materials from the suppliers (upward movement). Get to know what food brands must know about Product Recalls

The food supply chain has grown from a traditional network of manufacturers and suppliers to a large ecosystem of various processes involving a number of stakeholders.

The supply chain integrates the fragmented processes into a cohesive system with value addition.

Six objectives of a food supply chain

Optimized Supply Chain Management

Competition in the food industry has made it necessary to have a quality and efficient supply chain system.

Today’s consumer wants a detailed report of the product they consume.

The disease and illness outbreaks are a concern and recall systems need to be efficient.

- Initially, it’s about getting the right source and the right method of sourcing. Quality and safety methods have to be ensured while selecting a source. Proper audits and contracts have to be made with parties for smooth functioning.

- Transparency throughout the supply chain is vital and with transparency comes trust. This allows stakeholders to work in tandem with a common goal in mind.

- Distribution and inventory are two major aspects of post-production. Selecting the right method for logistics and delivering on time can only be achieved through proper inventory management.

Reduce Order time

Order time refers to the time that the supply chain takes from procurement of raw materials to the final product reaching the consumer, excluding the time taken to deliver the product. In short, it’s the time that the organization takes to manufacture a finished product.

Why is this important? This time taken to produce is a KPI (Key Performance Indicator) to determine the efficiency of the organization’s responsiveness to consumer demands. These can be improved by setting up constant time monitors, protocols and time limits

Cost Quality Balance

Global trade has expanded the current marketplace. Logistics and exchange are major issues in the quality and safety of a product.

There are operational variables such as inventory, quality process and pricing that affect different supply chains.

What is the preservation time? Which warehouse management is best for cost-cutting? These decisions must be based on the storage of perishable food products and their required delivery procedures. These determine the pricing of a product. Hence it is critical in managing operations efficiently and effectively with keeping in mind the cost-quality balance.

Quicker Delivery Time

This refers to the time taken by a product after production to reach the hands of the consumer. This post-production journey is mostly managed by the distributing channels.

The selection of a proper and effective distribution method plays an important role in faster delivery. Inventory management, Blockchain technology, automation, delivery tracking, etc. help in managing product safety, quality and timely delivery.

Four key factors affecting delivery are,

- Order management: Here customer orders or requirements are processed and stimulated. A firm manifests its obligation on quality safety and delivery time.

- Inventory management: Changes in trend and demand cause imbalance in operations. Hence inventory management acts in binding production with consumer demand.

- Warehouse management: For timely delivery to consumers, planning and execution in terms of receiving, managing, storing, delivery and retrieving are important.

- Transportation management: A logistics manager has to manage the final transport network to the customers. Various parameters like mode of delivery, number of crew members required, turnaround ratio, infrastructure, traffic control and government regulations determine the final delivery time.

Inventory Optimization

Inventory optimization isn’t just warehouse management; it’s the next leap in maintaining the right amount of inventory to meet demand while keeping logistics costs low. This is performed through data analysis, forecasting, strategies and smart decisions. It is estimated that 65% of products are returned due to improper packing and bad logistic methods.

Inventory optimization is performed in many ways, among which a few are listed below,

- Inventory review: Adaptation of a reviewing system keeps in check product availability, product demand and shelf life. Continuous review and periodic review are the two major ways of reviewing. Stock management systems like base stock method, LIFO (Last In First Out), FIFO (First In First Out), HIFO (Highest In First Out), etc help in the valuation of inventory and help in reordering.

- Forecasting: There are abundant technologies like Blockchain, AI (Artificial Intelligence), IOT (Internet Of Things), and multi-model simulations which help determine trends and consumer demand with the help of proper data. These help in maintaining optimal stock levels and also predicting future requirements.

- JIT (Just In Time): Modern world customers demand a variety of products. Leveraging on JIT principles helps avoid inventory issues such as overstocking, stock-outs and backorders. Inventory optimization is achieved through purchasing inventory when demand is created and delivering just in time.

Improved distribution

Distribution happens in the second half of the supply chain, i.e. post-production processes such as packing, warehousing, inventory management and logistics. In brief, it is every process that takes place after a product is manufactured, until it reached the hands of the customer. Having a good distribution management system would help in faster and on-time delivery, quality and safety maintenance, efficiency and cost-reducing. An organization has to be quick in delivery to survive today’s competitive world.

Some of its advantages are,

- Systematic movement: With transparency within the supply chain, the management of products becomes much simpler. Market demands, trends and consumer feedback help in formulating inventory decisions, and promotional strategies and counter varying demands while maintaining stocks at every channel.

- Cost reduction: Distribution management selects the required type of delivery, storage conditions, warehouse management, etc. It provides the right price for a product while supporting the marketing strategy.

On the whole, the food industry looks simple but showcases intricacies when dived into. A good supply chain and its management along with technology act as tools to simplify this complex web of operations.

As Albert Einstein quoted “Necessity is the mother of all inventions”. As the markets evolve, new tools and strategies are developed to act in sync with the industry.

Traceability is important to transform supply chains and see improved value and benefits. It would also drive supply chains towards environmental and social sustainability. Blockchain-powered traceability solutions empower the supply chain with improved efficiency, transparency, visibility, and reduced time and transactional costs.

Check how blockchain helps to revolutionize the food supply chain.